Climate change has turned environmental responsibility from a trendy slogan into a real challenge that demands concrete action. Every year, the world generates about 2.6 billion tons of solid waste, but only 16% is recycled into secondary raw materials. The rest ends up in landfills, threatening ecosystems and worsening the climate crisis. That’s why at KAN, reducing our environmental impact is not just a goal — it’s a long-term commitment that we pursue every day with full dedication.

Giving Materials a Second Life — Not Just Disposing of Them

Our ultimate goal is full environmental neutrality. We are constantly improving our methods for managing and utilizing production waste. More than 95% of waste generated at our plant can be reused or recycled. We hand over these materials to specialized companies that handle them professionally. This helps us minimize harm to the environment and implement circular economy principles that allow us to:

- Reduce the use of new natural resources

- Decrease the amount of waste sent to landfills

- Reuse materials in our own production processes

- Build sustainable supply chains based on environmental responsibility

As Sławomir Kościuczuk, Business Development Director at KAN Group, explains:

“For many companies, production waste is a problem. For us, it’s part of the process — one that we manage effectively through well-planned actions and cooperation with experienced partners. Some materials are reintroduced into our production, while others are sent to companies specializing in polymer waste recycling. This makes it possible to recover wax, metals, and pyrolysis oils in three distinct fractions with different properties and uses. This approach not only reduces waste but also allows us to reclaim valuable resources. That means we’re taking care of both process efficiency and the environment.”

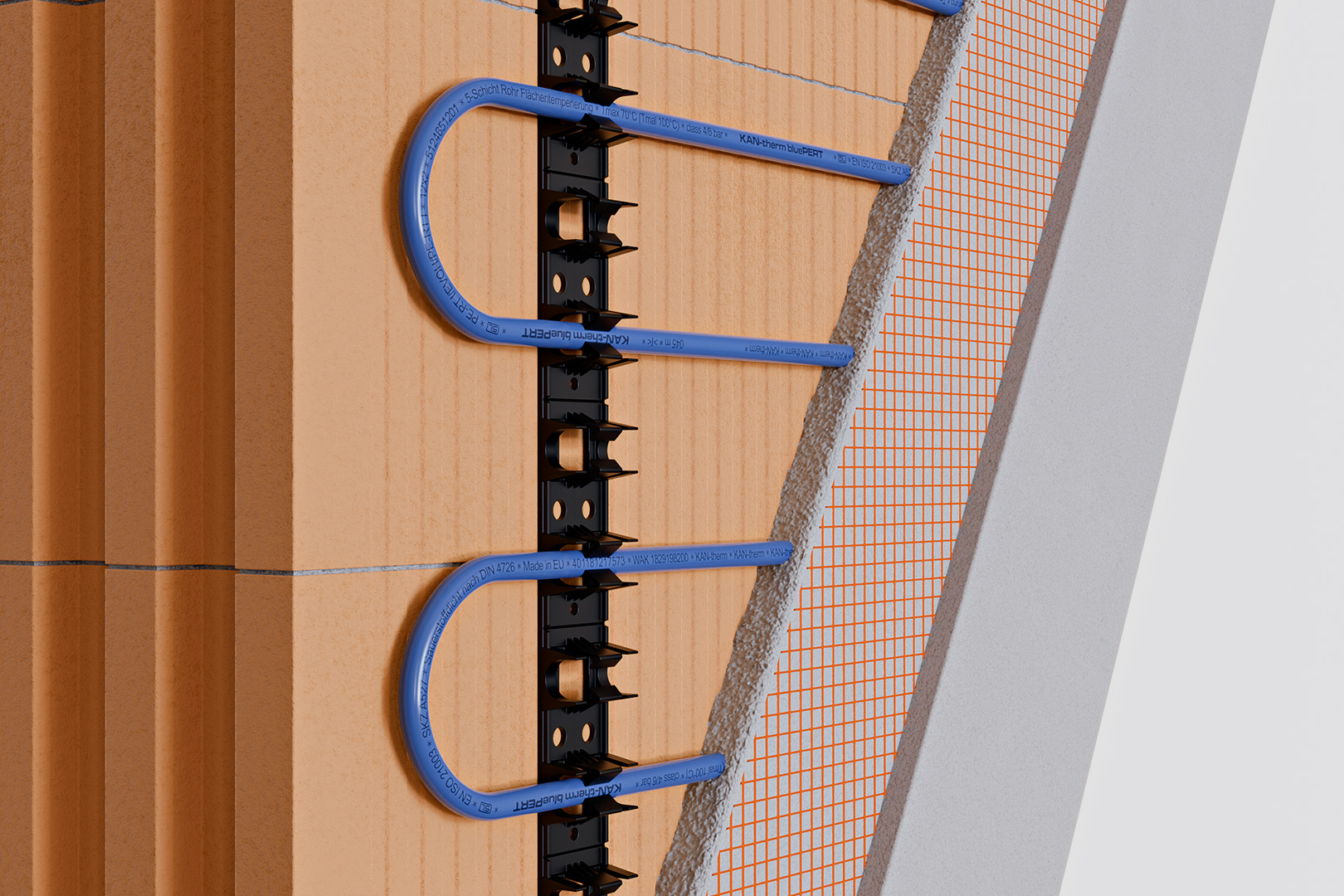

Technology That Supports Our Environmental Goals

Our factory combines cutting-edge technology with a true commitment to sustainable development. A modern machine park, together with an ERP system, gives us full control over every stage of production — from real-time monitoring to efficient management and optimization. This helps us reduce errors, improve operations, and genuinely limit our environmental footprint.

In addition, we operate a specialized laboratory at the plant where new materials and technologies are tested. We also run internal quality checks — every product batch is carefully assessed before being released. As a result, our processes meet the requirements of ISO 9001 and other industry standards for quality and environmental compliance.

Sustainability is the foundation of our strategy. It brings together ecological responsibility and production efficiency. By investing in modern technologies and using resources wisely, we are steadily reducing the impact of our operations on the environment — helping to preserve the planet and improve the quality of life for everyone.