KAN-therm ultraPRESS system is a modern, complete installation system consisting of PERTAL polyethylene pipes with an aluminium layer and PPSU plastic or brass fittings, with diameter range from 16 to 63 mm.

KAN-therm ultraPRESS changes the functionality of water and heating installations. It was designed to optimise the installers’ work and provide reliable and efficient installation solutions.

Advantages of KAN-therm ultraPRESS system

In a world of professionals, KAN-therm ultraPRESS system is synonymous to:

- comfort - safe and easy installation by eliminating the need for pipe calibration and chamfering (in the 16-32 mm diameter range)

- safety - special design of the steel crimping ring for automatic, correct positioning of the press jaw. This design solution eliminates assembly errors caused by incorrect positioning of the pressing jaws.

- universal design - you can use press jaws with two different crimping profiles: 16-40 mm (U or TH), 50-63 mm (TH).

Its key benefits also include:

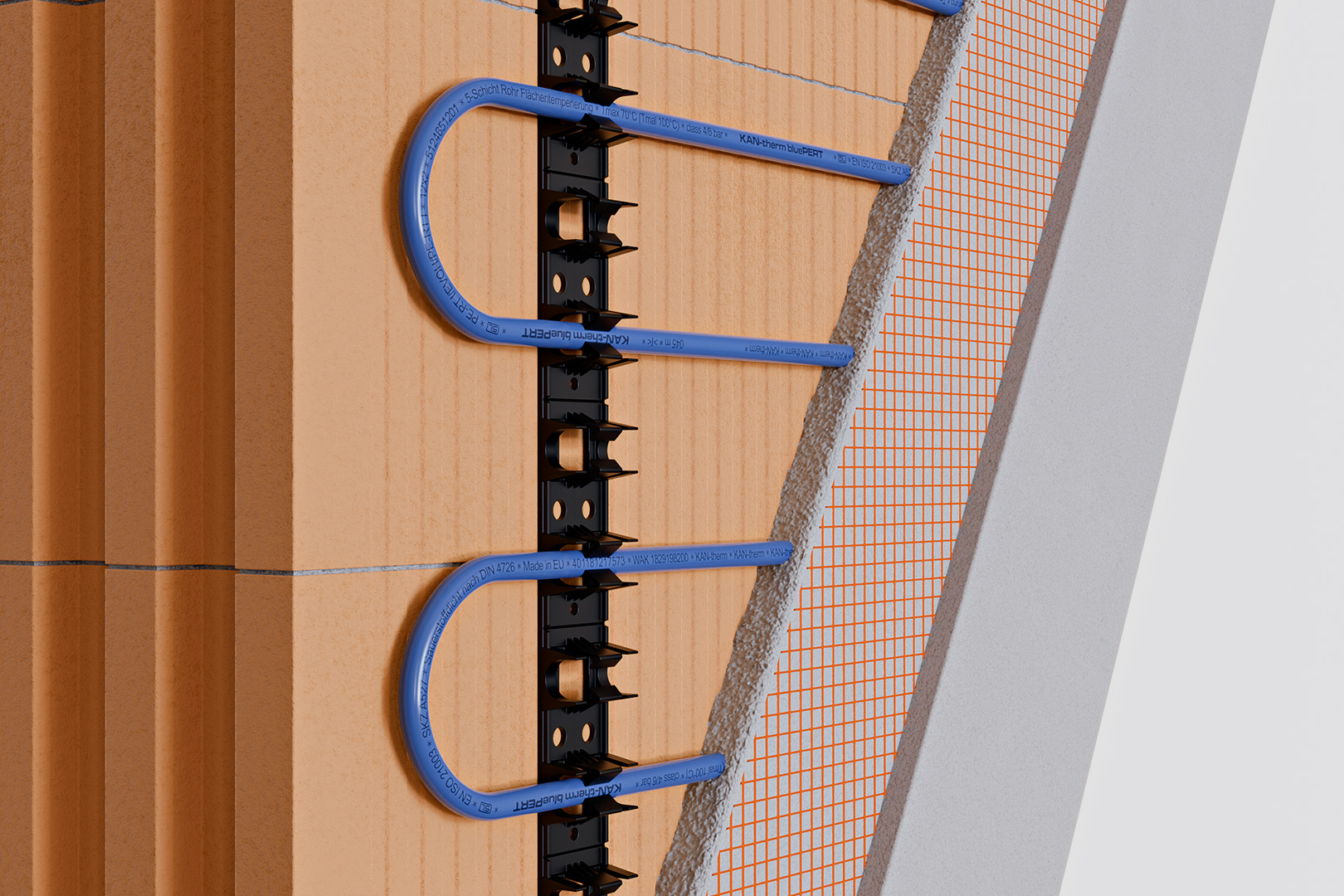

- compatibility - fittings are compatible with PERTAL pipes with aluminium layer. In addition, it is possible to connect PERT, PEXC and bluePERT pipes with an EVOH layer.

- easy identification - thanks to the coloured plastic rings in the 16-40 mm diameter range, identifying the diameter of a fitting has never been easier!

- LPB (Leak Before Press) - an unpressed connection signalling function (in the 16-32 mm diameter range) that allows leaky connections to be detected even while the installation is being filled with water, in accordance with DVGW guidelines.

Assembly is speed, comfort and safety

Tight and secure connections in KAN-therm ultraPRESS system are achieved by crimping a steel ring onto the pipe and fitting. Easy-to-use and versatile tools are used to make the connections. The connections do not require additional seals such as tape or oakum. KAN-therm ultraPRESS system has been designed on the basis of the "quick installation and long-lasting effect" principle, which allows for a measurable acceleration of investment and finishing works.

The installation of KAN-therm ultraPRESS system for fittings with diameters of 16, 20, 25, 26, 32 and 40 mm is slightly different than for diameters of 50 and 63 mm. Regardless of the fitting size, press type connections should be made at temperatures above 0 °C.

Installation of KAN-therm ultraPRESS with diameters of 16, 20, 25, 26, 32 and 40 mm

- Start assembling KAN- therm ultraPRESS connections by cutting the pipe perpendicular to the axis to the required length. Make sure that the cutting tools you use (PERTAL pipe cutter or roller cutters) are sharp!

Why is it so important? In the case of KAN-therm ultraPRESS fittings with diameters of 16-32 mm, chamfering of the pipe edge is not required, provided that sharp cutting tools are used and the pipe is axially assembled with the fitting. For larger diameters (25 mm and over), the use of a calibrator is recommended to facilitate sliding the pipe onto the connector spigot. With a diameter of 40 mm, pipe calibration is necessary. - Give the pipe a suitable shape, respecting the minimum bending radius R >5 Dz. When using a mechanical bending machine for diameters of 16-20 mm, the minimum bending radius is R >3.5 Dz. Perform the bending at a distance of 10 × Dz from the fitting.

- Push the pipe into the fitting as far as it will go, keeping the pipe axially mounted on the fitting spigot.

- Check the insertion depth of the pipe. The inspection holes in the steel ring must be completely covered by the pipe embedded in the fitting. If you are using a crimping machine with a "U" type jaw - place the jaw precisely on the steel ring between the plastic spacer ring and the flange of the steel ring, perpendicular to the axis of the fitting spigot. For tools with a "TH" profile, the jaw is positioned on a plastic spacer ring (the ring must be covered by the outer groove of the jaw). In both cases, the design of the fitting prevents uncontrolled movement of the press jaws during the pressing process.

- Start the press drive and make the connection. The pressing process continues until the tool jaws are fully closed. Pressing the ring onto the pipe can only be done once.

- Unlock the jaws and remove the tool from the crimped ring. The connection is ready for the pressure test.

Installation of KAN-therm ultraPRESS with diameters of 50 and 63 mm

1. Cut the pipe perpendicular to the axis with a roller cutter.

2. Calibrate the pipe and chamfer its inner edges with a calibrator no deeper than the aluminium layer.

3. Insert the correctly calibrated pipe end into the fitting.

4. Check the insertion depth of the pipe - the inspection holes in the steel ring should be completely covered by the pipe embedded in the fitting.

5. Place the crimping jaws on the steel ring perpendicular to the axis of the fitting.

6. Place the jaw of the crimping machine on the ring so that it contacts the flange of the connector. The outer edge of the jaw should be flush with, but not encompass, the fitting flange. Start the crimping machine drive and make the connection.

7. Remove the crimping jaws from the completed connection.

Thanks to the unique design of the components, installation of KAN-therm ultraPRESS system is extremely simple, fast and, above all, safe.